Campomatic C46VM Manuale d'uso

Pagina 24

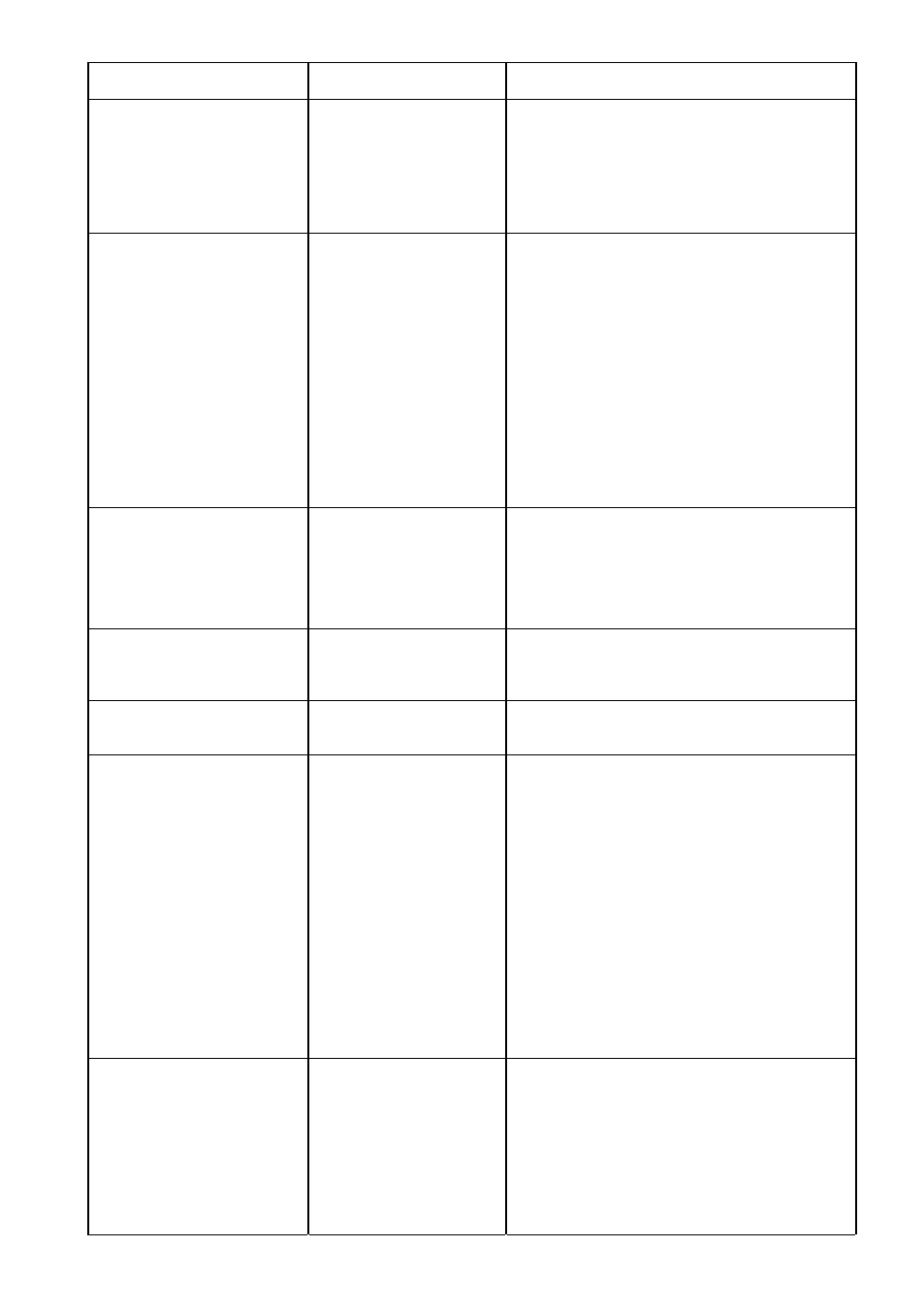

FAULT‐FINDING GUIDE

WORKING FAULTS

POSSIBLE CAUSES

SOLUTION

All the lights on the

command panel blink.

Overheating; circuit board

damage

Turn the machine off and wait around 15

minutes for it to cool down and for the thermal

protection to be automatically restored.

If, on switching the machine back on, the

same problem occurs, call a service

technician to replace the power board.

The STOP button light

blinks accompanied by an

intermittent acoustic

signal.

Insufficient vacuum in the

chamber (the vacuum

chamber does not signal

the minimum vacuum

having been reached to

the power board).

Lid not pressed down at the start of

the cycle.

Lid of the preserving jar badly

positioned

Lid seal worn or badly positioned.

The intervention of a technician is

required to check the air circuit, the sensor

board and the vacuum pump.

The intervention of a technician is

required to check the correct electro valve

opening.

Vacuum pump in thermal protection

state: switch the device off and wait around 15

minutes.

When switching on, all the

lights on the command panel

blink for 3 seconds and the

acoustic signal is audible

(long Beep).

Oil change warning due to

having reached 2500

working cycles.

Intervention of a technician required for

pump oil substitution.

The cycle starts up

(blinking buttons) but the

pump does not start up.

Pump thermal protection

intervention due to

overheating.

Switch the device off and wait around 15

minutes before switching the power back on.

The machine will not

switch on.

Energy shortage.

Check the electrical connection.

Low vacuum level in the

bag

1) Irregular

bag

soldering

2) Irregular

bag

soldering line

3) Dirty or perforated

bag.

4) Insufficient

soldering.

5) Bag size not suitable

for the size of the

product.

6) Insufficient

pump

performance.

1)

Position the bag correctly.

2)

Check the state of the Teflon cover.

Technical intervention to substitute the Teflon

and check the soldering resistance.

3)

Change the Bag.

4)

Choose a bag where the volume of

the product is not more than 2/3 of the

volume.

5)

Intervention of a technician required

to check the pump

The device does not solder

the bags.

1) Dirty

contacts.

2) Soldering resistance

bar broken.

3) Power

shortage.

4) 3-way electro valve

blocked or dirty.

1)

Remove the soldering bar from the

two screws and clean the two bar contact

holes with a small brush.

2)

Intervention of a technician required

for its substitution.

3)

Intervention of a technician required

to check the leads and the power board.

4)

Intervention of a technician required

for its substitution.

24