Campomatic C46VM Manuale d'uso

Pagina 22

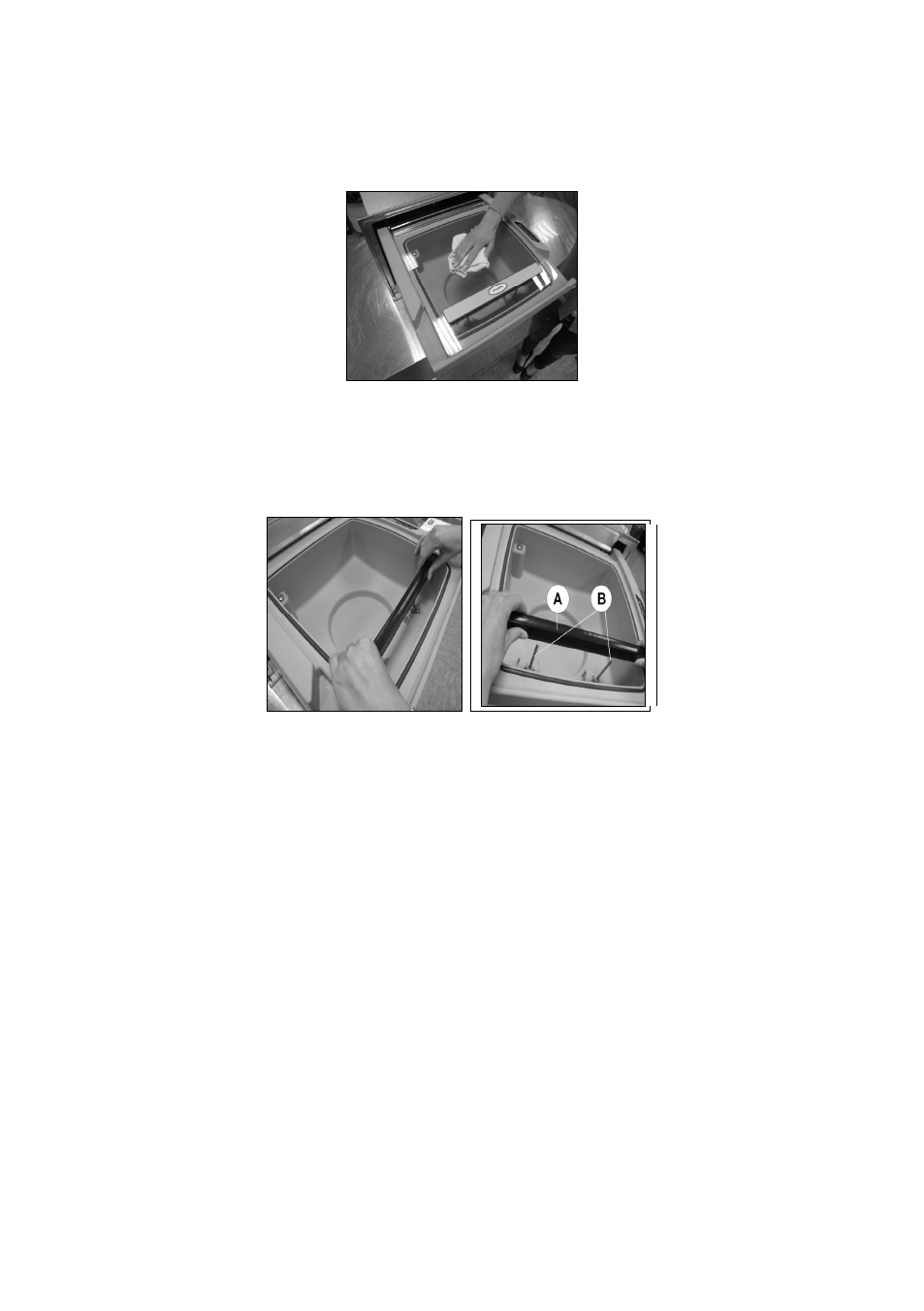

Cleaning the glass lid

Caution! Switch off the power supply before each maintenance intervention.

In the same way, cleaning the glass lid is recommended after use.

The use of a soft cloth or non-abrasive sponge is recommended, which has been soaked in tap

water, or a specific product for cleaning glass.

Cleaning the soldering bar

Caution! Switch off the power supply before undertaking the maintenance intervention.

On a monthly basis, it is advisable to clean the surface of the soldering bar in order to remove

residues that could affect the bag sealing quality.

In order to do so, lift the soldering bar (A) upwards and extract the two screws (B).

The use of a soft cloth or non-abrasive sponge is recommended and a neutral detergent or a

disinfecting alcohol-based substance.

When you have finished, insert the bar onto the two screws (B) centering the two holes on the

lower part of the bar and ensuring that it is correctly inserted.

Caution: do not remove the black Teflon strip! Do not use scrapers or abrasive utensils!

Dehumidifying the pump oil.

The heart of the machine is its vacuum pump. To ensure the pump does not oxidise on its internal

surfaces and consequently cause the blockage of the rotors due to residues of rust, which occur

when water vapour is drawn in with air, which then condenses and remains inside the pump for

long periods of time, it is necessary to undertake the following:

1. Pack the product when it is cold, possibly at 3-4°C. The hotter the product, the shorter the

preservation and the greater the formation of condensation inside the pump, with the resulting

rust and damage.

2. If the device is only used occasionally, before packing the products, run at least two-three

complete "Long preserving jar" cycles with the chamber empty. This enables the temperature

of the pump oil to come up to the right level and the water vapour to be evacuated.

22