Powermax1000, Manuale di manutenzione, Normal mode – Hypertherm Powermax1000 Rev.1 Manuale d'uso

Pagina 76

1

6-2

powermax1000

Manuale di manutenzione

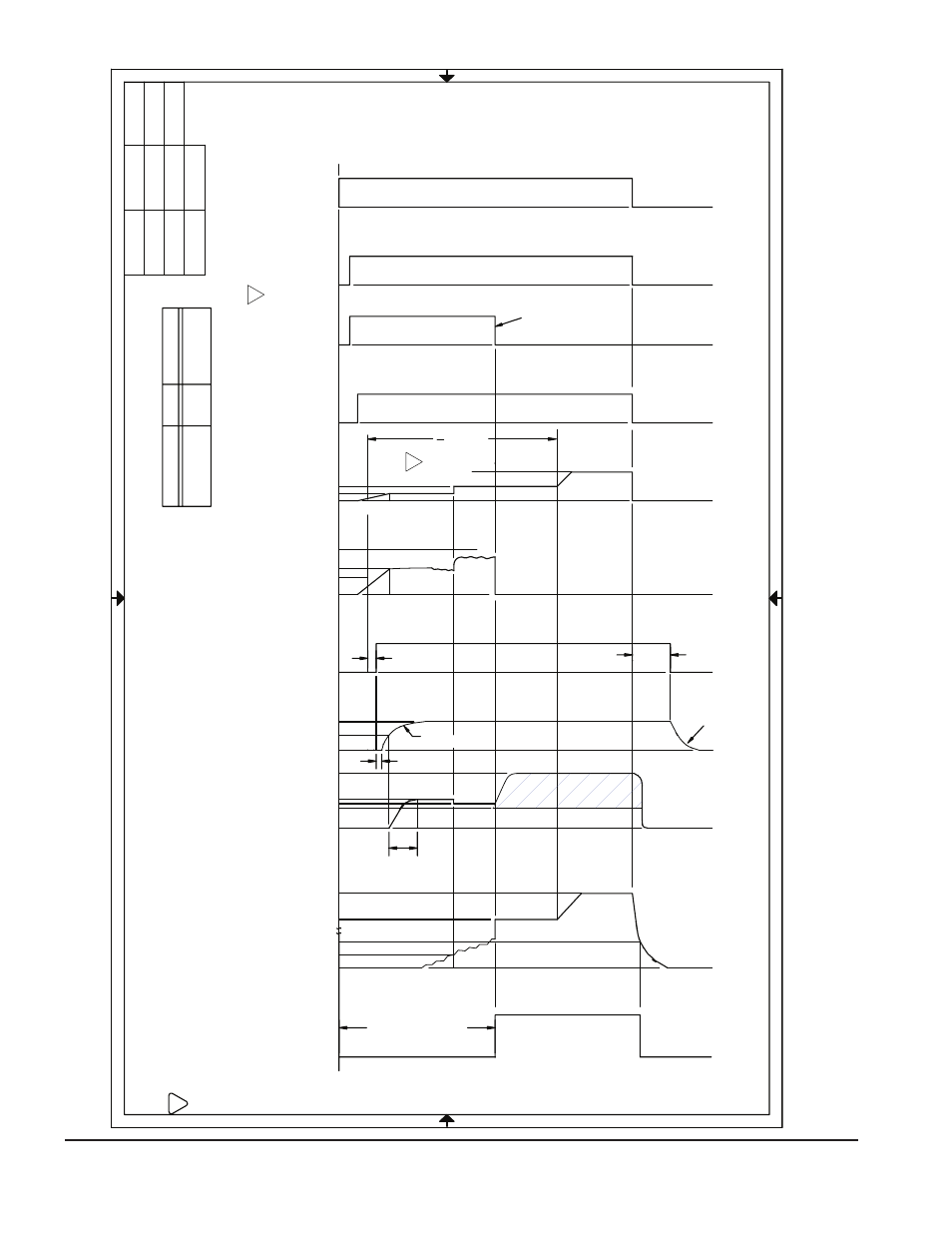

t=0

1

0

Start

t

Start

0

1

2ms

Debounced

Arc

0

Pilot

1

2ms

Digitized

XFR signal

Enable

Inverter

0

1

3ms

(

INV_EN

)

Icommand

0

25A

3ms

Setpoint

8

0

16

12ms

Ipilot

(Amps)

Gas

0

1

Postflow

60

Pcritical(15)

at Torch

(psi)

Gas Pressure

Time

x

Consumable

Re-Seat

0

225

Voltage

Arc

(volts)

~

~

10ms

typ

250

1.6

25

I Setpoint

0

(amps)

I Work Lead

10.0 sec

NORMAL MODE

1ms

25

150

210

0.4

16A

valid

3ms

tdelay

0

1

If > 5.0 sec

pilot arc time out

XFR signal

Digitized

in DSP and

Switch

Constant

T

orch Lead

Length(feet)

50

50

tdelay

(msec)

T

ime Constant

(msec)

250

Machine Motion

12ms

1.75A/ms

1.75A/ms

1. 200ms DELA

Y

IS FOR

T

O

RCH LEAD

PRESSURIZA

TION.

> 200 ms

1.

2. CURRENT

(I) V

A

LUES SHOWN FOR 80A

UNIT

.

I cut max

60A

UNIT

80A

UNIT

80

60

I cut min

25

20

I pilot

16/25

1

4/20

REQUIREMENTS PER HYPER

THERM P/N 048266.

3. RoHS/WEEE COMPLIANT

AND OTHER REGULA

T

O

R

Y

D