Parkside PWSZ 125 B2 Manuale d'uso

Pagina 2

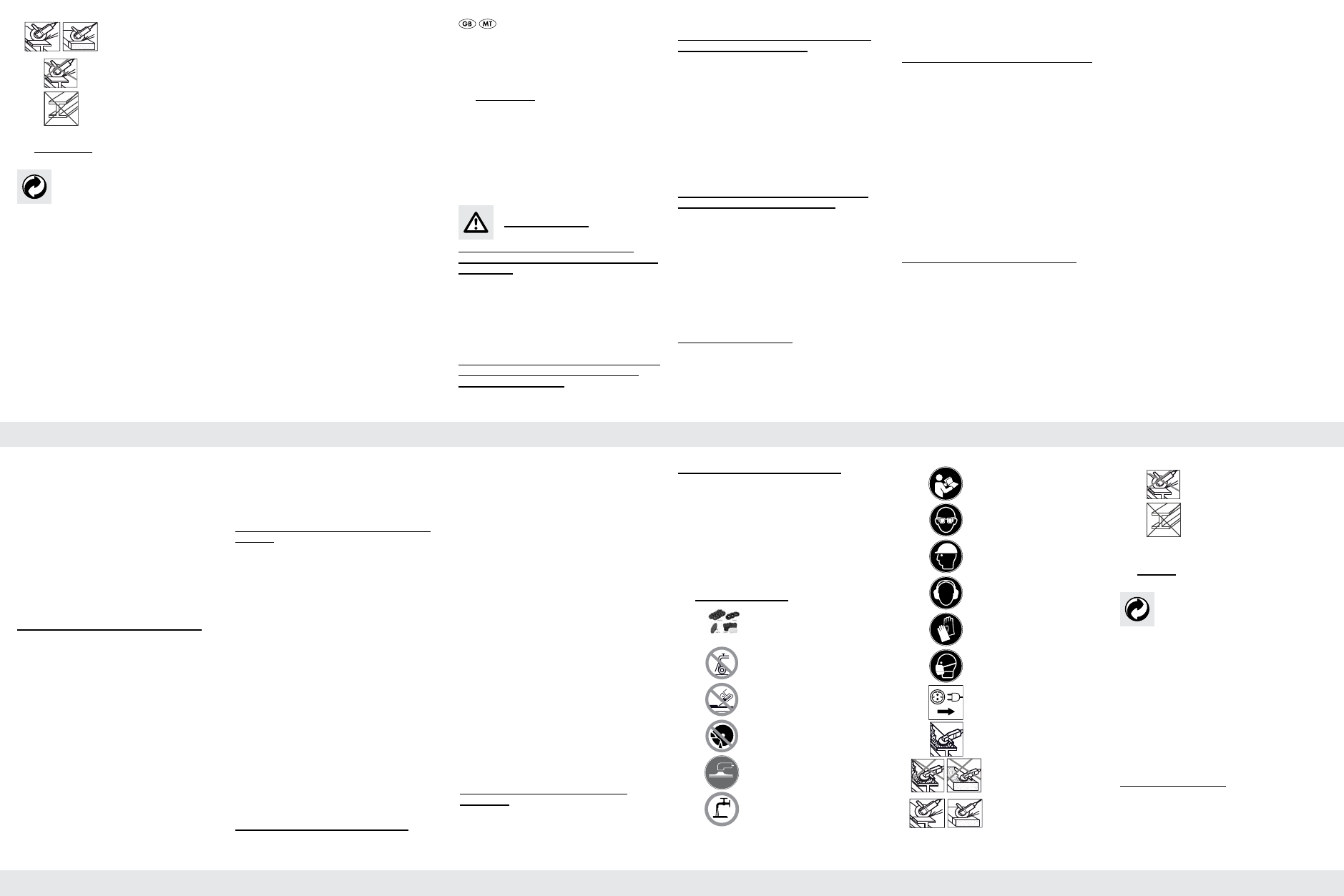

Solo per troncatura

Non adatto a troncatura

Non adatto alla lavorazione

del metallo

§

Smaltimento

La confezione è prodotta in materiale

riciclabile e biodegradabile, smaltibile nei

luoghi di raccolta differenziati.

Potete informarvi sulle possibilità di smaltimento del

prodotto consumato dall‘amministrazione comunale e

cittadina.

Not for cutting

Not approved for working

with metals

§

Disposal

The packaging is made entirely of recyclable

materials, which you may dispose of at local

recycling facilities.

Contact your local refuse disposal authority for more

details of how to dispose of your worn-out product.

Heed all safety instructions

Use protective eyewear

Wear a safety helmet

Use ear protection

Wear safety gloves

Use a dust mask

Unplug

Only for roughing / Only for

grinding

Not for roughing

Only for cutting

Safety instructions for steel brushes

Please note that steel brushes lose steel

pieces during normal use. Do not apply

too much pressure to steel brushes. Failure

to heed this warning may lead to injury due to flying

steel pieces.

When the use of a safety cover is recommended,

prevent the safety cover and steel brush from coming

into contact with one another. Please note that

the diameter of disk brushes and cup brushes can

increases due to pressure and centrifugal force.

§

Meaning of symbols

Not approved for hand-held

or manually-guided grinding

Not approved for wet

grinding

Not approved for side

grinding

Do not use if damaged

Only approved with a

backing pad

Only approved for wet

cutting

Overstressing the cutting disk increases its

risk of jamming or blocking and thus the likelihood

of kickback or damage to the attachment itself.

Avoid the area directly in front of and

behind the rotating cutting disk. When

moving the cutting disk across your workpiece away

from your person, the tool may be hurled in your

direction in the event of kickback.

Turn off the device is the cutting disk jams

or if you wish to interrupt working. Hold

the device calmly and allow all rotating parts to

come to a complete stop. Never attempt to pull any

rotating parts from the cutting site. This may cause

kickback.

Do not turn on the device while it is still in

the workpiece. Your cutting disk should reach

its full speed before you continue angle grinding.

Otherwise the disk may jam, jump back from the

workpiece and cause kickback.

Support boards and large workpieces

to prevent the risk of kickback due to

a jammed cutting disk. Large workpieces

may bend due to their own weight. Support large

workpieces on both ends and near the cutting site.

Exercise extreme caution when cutting

into existing walls and other areas where

vision is limited. Your cutting disk may kickback

if it comes into contact with gas, water and electrical

lines or other objects.

Safety instructions for grinding with

sandpaper

Heed the manufacturer’s instructions for all sanding

sheet sizes. Do not use sanding sheets that are too

large. Sanding sheets that extend over the disk can

lead to injury and blocking. The sanding sheet may

also tear, causing kickback.

tool attachments from jumping back from

the workpiece and jamming. The rotating

tool attachment tends to jam when working on

corners, sharp edges or when it jumps back from the

workpiece. This leads to loss of control or kickback.

Safety instructions for grinding and cut-off

grinding

Only use grinding wheels that are approved for use

with your power tool and the proper safety cover.

Grinding wheels not approved for use with your

power tool may not be shielded sufficiently and are

therefore unsafe for use.

The safety cover must be attached to

the power tool and adjusted so that

maximum safety is guaranteed, that is, as

little of the grinding wheel as possible is

open toward the operating individual. The

purpose of the safety cover is to shield the operating

individual from broken pieces or accidental contact

to the grinding wheel.

Grinding wheels may be used only for

their intended purpose. For example, never

grind using the side of a cutting disk. Cutting disks

are intended to cut materials using the disk edge

only. Applying pressure to the side of the disk may

cause it to break.

Always use undamaged clamping flanges

of the right size and proper form for the

grinding disk you’ve selected for use. The

right flange supports the grinding disk and thus

minimizes the risk of it breaking. Flanges for cutting

disks may differ from flanges for grinding disks.

Safety instructions for cut-off grinding

Avoid your cutting disk from blocking

and do not apply too much pressure.

attachments. If you lose control of the device, the

power cable may be severed or caught, causing the

rotating attachment to come into contact with your

hand or arm.

Allow all tool attachments to come to a complete

stop before setting down your power tool. Rotating

attachments may come into contact with the surface.

This may cause you to lose control of the power tool,

leading to injury of yourself or others.

Turn off the power tool when carrying it about. Your

clothing may otherwise become tangled up in the

rotating attachment, causing personal injury.

Do not use the power tool near flammable materials.

Sparks may ignite such materials.

Kickback and related safety instructions

Kickback is a sudden reaction arising when a rotating

power tool attachment, such as a grinding disk, buffing

disk, wire brush, etc., snags or jams.

Kickback is the result of improper use of the power

tool. Heed the following safety precautions to prevent

kickback:

Always maintain a firm grip on the power tool and

use any available additional handle to better control

kickback.

Keep your hands away from rotating

tool attachments at all times. The attachment

may come into contact with your hand in case of

kickback.

Keep your body out of the area that

the power tool would enter in case of

kickback.

In case of kickback, your power tool will jump in the

direction opposite to that in which the grinding disk

is moving.

Exercise extreme caution when working

on corners, sharp edges, etc. Prevent your

User manual

CUTTING/GRINDING DISC SET (Z31677A)

FLAP DISC SET (Z31677B)

HOOK & LOOP GRINDING PLATE (Z31677C)

SANDPAPER SET (Z31677D)

§

Intended use

This product is not intended for commercial use.

BEFORE FIRST USE, FAMILIARIZE YOURSELF

WITH THE PRODUCT’S INSTRUCTIONS FOR

USE AND SAFETY INSTRUCTIONS! IF YOU GIVE

THE PRODUCT TO A THIRD PARTY, YOU MUST

INCLUDE ALL DOCUMENTS. SAVE ALL SAFETY

INSTRUCTIONS AND INSTRUCTIONS FOR USE

FOR FUTURE REFERENCE!

Safety instructions

General safety instructions for coated

grinding and buffing tools, driver pads and

cup brushes

Grinding/buffing tools are prone to breakage.

Exercise extreme care when handling grinding/

buffing tools.

Check grinding/buffing tools and brushes for

damages before use. Do not use any damaged tools

or incorrectly assembled grinding/buffing tools or

brushes.

Selecting coated grinding and buffing tools,

driver pads and cup brushes for secure

footing and proper use

Heed all safety instructions belonging to the

grinding/buffing tools as well as the notes on proper

use or safety instructions.

Storing coated grinding and buffing tools,

driver pads and cup brushes

Handle and transport grinding/buffing tools with

care.

Store grinding/buffing tools so that they are

not exposed to mechanical stress or damaging

environmental factors (i.e. moisture).

Store brushes so that they are shielded from the

following:

- high humidity, heat, water (or other liquids), acids

or vapors. Also avoid low temperatures which may

cause condensation to form on the brushes when

they are moved to spaces with a higher temperature.

Deformation of a brush component.

Before using coated grinding and buffing

tools, driver pads and cup brushes

Always check grinding/buffing tools for damages

before use.

Do not use any damaged grinding/buffing tools or

brushes.

Rust build-up or other signs of chemical or

mechanical alteration to the fitting equipment of

brushes may cause premature failure of the tool.

Brushes and grinding/buffing tools may not be

mounted to machines whose speed exceeds the

maximum speed of the brush or grinding/buffing

tool.

Instructions for mounting

Following the instructions included with the grinding/

buffing tool and those of the machine manufacturer

to mount grinding/buffing tools and brushes.

Make sure to use brushes and grinding/buffing

tools only with devices that have an appropriate tool

attachment.

After mounting, always do a small test run. Do not

exceed the maximum labeled speed of the grinding/

buffing tool or brush.

Grinding/cutting operation (if applicable)

Follow the instructions for use provided by the power

tool manufacturer.

Mount all safety attachments to the machine before

use.

Use appropriate personal safety equipment

depending on the machine and type of use, such

as: protect face and eye wear, ear protection,

respiratory protection, safety shoes, safety gloves

and any other necessary protective clothing.

Use the grinding/buffing tool for appropriate

grinding/buffing jobs only.

For angle grinder work with hand-held grinding

tools, insert the cutting tool evenly into the cutting

gap. Do not tilt the hand-held machine.

Turn off your hand-held angle grinder and allow it to

stop rotating before setting it down on the ground or

your workbench.

Safety instructions for all types of use

Safety instructions for grinding, grinding

with sandpaper, working with wire brushes,

polishing and cut-off grinding

Do not use any equipment von expressly intended

for use with and recommended by the manufacturer.

The ability to successfully mount equipment to your

power tool guarantees safe use in no way.

The maximum speed of the attachment must be

at least as high as that of the power tool. Running

attachments at speeds that exceed their maximum

rated speed may cause them to break, release from

the power tool and cause injury.

The exterior diameter and thickness of the

attachment must correspond to the size requirements

of your power tool. Incorrectly measured

attachments cannot be sufficiently shielded or

controlled.

Buffing disks, flanges, grinding disks and other

equipment must fit exactly on your power tool’s

reception spindle. Attachments that do not fit exactly

on your power tool’s reception spindle turn unevenly,

vibrate heavily and may cause a loss of control.

Do not use any damaged attachments. Before use,

always check your attachments for damages. Check

buffing disks for cracks and tears, grinding disks for

tears or high wear, steel brushes for loose or broken

wires.

If you drop a power tool or attachment, check it for

damages or use undamaged attachments. You and

all people in your vicinity should keep on a different

level as the rotating attachment as soon as you have

mounted it.

Wear personal protective clothing. If necessary,

wear a full protective mask, eye protection or

safety glasses. If necessary, wear a dust mask, ear

protection, protective gloves or a protective apron to

shield yourself from grinding and material particles.

Safety glasses shield your eyes from airborne

foreign objects that may develop during many types

of work. A dust mask or respiratory protection filter

dust. Extended exposure to loud noises may lead to

hearing loss.

Make sure that anyone who enters your workspace

is wearing appropriate personal protective clothing.

Broken pieces of the object you are working on or

broken pieces from your tool attachments may fly

around and cause injury even outside your direct

working vicinity.

Keep the power cable away from all rotating tool

GB/MT

GB/MT

GB/MT

GB/MT

IT/MT

GB/MT

IAN 93533 - PWSZ 125 B2

OWIM GmbH & Co. KG

Stiftsbergstraße 1

D-74167 Neckarsulm

Model No.: Z31677A, Z31677B,

Z31677C, Z31677D

Version: 10/2013